Navigation article:

An eraser is really a object which is used to get rid of marks from paper. Most erasers are made to remove pencil marks. Other erasers are created to be utilized on typewriter marks. Some kind of special pens contain erasable ink that may be removed by erasers. Although some erasers are offered individually by means of wide, slender blocks, a lot more erasers are located permanently mounted on pencils. Other erasers are created to temporarily affix to pencils. Some erasers are enclosed in wooden cases that resemble pencils. These erasers, made to be sharpened like pencils, frequently possess a brush attached. This really is accustomed to brush away small bits of the eraser left out after it removes an indication. This kind of eraser is generally accustomed to remove typewriter marks.

The very first erasers were bits of bread. There wasn’t any better substance for removing pencil marks until rubber was obtainable in that old World. Rubber was recognized to the occupants of Central and South Usa lengthy before Europeans found the ” New World “. As soon as the eleventh century, it had been accustomed to coat clothing and also to make balls. It had been also accustomed to make footwear and bottles by flowing the liquid form on earthen molds and letting it dry.

In 1735, in france they researcher Charles en Condamine described an ingredient referred to as caoutchouc and sent samples to Europe. Caoutchouc was produced from a fluid created underneath the bark of the tree present in tropical regions of the ” New World “. This milky liquid, referred to as latex, continues to be accustomed to make natural rubber.

Caoutchouc was initially recommended to be used being an eraser within the Proceedings from the French Academy in 1752, most likely by Jean de Magellan. In 1770, the British researcher Frederick Priestley recommended that caoutchouc be named rubber, due to its capability to rub away pencil marks. Also, he told readers of his book Familiar Summary of the idea and exercise of Perspective where you can purchase “a cubical piece, of approximately one-half inch, for 3 shillings.” Within the Uk, erasers continue to be referred to as rubbers.

Before the late nineteenth century, pencils and erasers were always separate. In 1858, Hyman Lipman of Philadelphia patented a pencil having a groove within the tip, into which an eraser was glued. Through the early 1860s, the Faber company made pencils with attached erasers. In 1862, Frederick Rechendorfer of recent You are able to City patented a noticable difference of Lipman’s design and sued Faber. The U . s . States Top Court determined that the thought of mixing a pencil by having an eraser couldn’t be patented. The reason behind this decision was the truth that mixing the pencil and also the eraser didn’t alter the purpose of either. This decision opened up the way in which for various companies to create pencils with erasers.

In 1867, a hollow eraser, into that your pencil might be placed, was introduced by J. B. Blair of Philadelphia. Earlier versions can also be known to possess existed. In 1872, the Bald eagle company made pencils with erasers placed into the wooden situation from the pencil. Others soon made similar pencils, which grew to become referred to as cent pencils simply because they were affordable. The supply of pencils with attached erasers in schoolrooms was initially questionable. It had been thought that the opportunity to correct errors easily will make students careless. Regardless of this concern, pencils with erasers were very popular. About 90% of contemporary American pencils are created with attached erasers. Pencils without erasers are a little bit more common in Europe.

Recycleables

The most crucial raw material within an eraser is rubber. The rubber might be synthetic or natural. Natural rubber is acquired from latex created through the rubber tree (Hevea brasilienesis). Synthetic rubber exists in a multitude of forms. The most typical synthetic rubber comes from the harmful chemicals styrene and butadiene. Styrene is really a liquid produced from ethylbenzene. Ethylbenzene is generally produced from ethylene and benzene, each of which come from oil. Butadiene is really a gas, derived either from oil or from substances referred to as butanes and butenes, which come from oil.

Other ingredients put into rubber include pigments that alter the colour of the eraser. White-colored could be created with zinc and titanium oxide. Red could be created by iron oxide. A number of other colors could be created with assorted organic dyes.

An essential component put into just about all rubber is sulfur. Sulfur enables rubber to become vulcanized. This method was introduced by Charles Goodyear in 1839. It uses heat and sulfur to create rubber stronger and resistant against heat.

Many other ingredients may be included to rubber. Included in this are vegetable oil, to help make the rubber softer and simpler to shape, and pumice, an all natural mineral making the eraser more abrasive.

The Manufacturing

Process

Making natural rubber

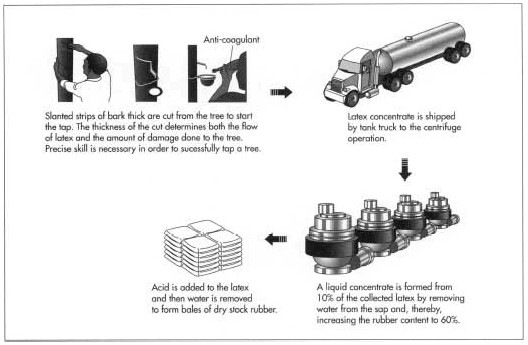

- 1 Rubber tree plantations are located only in tropical regions rich in amounts of annual precipitation. Malaysia may be the leading producer of rubber trees. A rubber tree is drawn on by cutting a skinny strip of bark about .04 in (1 mm) deep from the tree as up high because the worker can certainly achieve. Later strips is going to be cut below the first. Each strip reaches about midway round the circumference from the tree and slants downward in an position of approximately 30 levels to permit the latex to empty right into a container. When the latex is permitted to coagulate naturally, each cut will produce about 1 oz (28 g) of latex prior to the latex stops flowing following a couple of hrs. A compound may be relevant to the bark to avoid the latex from coagulating, letting it flow for a few days.

- 2 The collected latex goes through a sieve to get rid of foreign objects. Water is put into the latex and also the mixture is pumped into large horizontal tanks that contains aluminum partitions. Dilute acetic acidity or formic acidity is put into make rubber coagulate into slabs around the partitions. The slabs are sprayed with water when they go through a number of rollers. Excess water is taken away by another number of rollers. The slabs are packed in bales, usually weighing 225-250 lb (102-113 kg), the same shape as cubes a couple of foot (60 cm) on every side. The bales are coated with clay to avoid sticking, bound with metal straps, and shipped to manufacturers.

Making synthetic rubber

- 3 Based on what sort of synthetic rubber has been made, a multitude of manufacturing processes can be utilized. The most typical type of synthetic rubber, styrene-butadiene rubber, is generally produced in an emulsion process.

- 4 Various chemicals are acquired from oil by fractional distillation. This method involves heating oil to around 600-700° F (315-370° C) and allowing the vapor to feed a tall vertical tower. Because the vapor increases with the tower, it cools. Chemicals with various boiling points vary from gas to liquid at different points within the tower and therefore are collected. Chemicals with high boiling points stay in the liquid condition once the oil is heated and could be taken off the foot of the tower. Chemicals with really low boiling points remain by means of gases and could be taken off the top tower.

Making erasers

- 9 Rubber gets to the eraser factory and it is combined with pigments, vegetable oil, pumice, sulfur, along with other things that customize the qualities from the final product. Synthetic rubber is simpler to combine since it usually arrives like a powder or perhaps a liquid. Natural rubber usually comes to bales and should be pulverized into powder or dissolved inside a solvent prior to it being mixed.

Qc

The manufacturing of erasers is extremely automated, with reliable products produced in the millions every year. Experienced eraser manufacturers have refined the strategy used enough where extensive inspection is not required.

The recycleables shipped towards the manufacturer are provided by firms that are recognized to provide substances using the proper characteristics. If your new substance is provided, or maybe it develops from a new company, the eraser manufacturer may inspect so that it is sure it meets all specifications.

Merely a really small number of erasers have to be inspected to make sure that they’ve the correct physical qualities. Flats should be the right size to suit into boxes. Plugs should have the right dimensions to suit into ferrules. Report of erasers is crucial to how good they are effective. Experienced inspectors can certainly know if an eraser is simply too hard or too soft.

The Long Run

Erasers have continued to be mostly unchanged for several years. Enhancements in eraser technology could be made in the manner rubber is created. New chemical formulas are continually being designed to produce synthetic rubber with techniques which are more effective, less pricey, and which lead to products with increased helpful qualities. Genetic engineering may lead to rubber trees that leave more latex, or trees that leave latex with physical qualities that will make natural rubber production more effective.

An indication for the future of eraser design is viewed within the Ergoraser, a distinctive eraser from Levenger, a business focusing on very good quality writing supplies. The Ergoraser, developed after 2 yrs of research, is oblong and curved, similar to the form of a spoon.

The thumb fits within the curve during use in ways which is made to be comfy and efficient. Although very costly when compared with ordinary erasers, the Ergoraser offers to play a huge role later on for individuals who demand the greatest quality in simple objects.

Where to find out more

Petroski, Henry. The Pencil. Knopf, 1990.

Source: www.madehow.com