Navigation article:

Parker Pen Trim Lathe

Wisconsin Historic Museum Object – Feature Story

Trim lathe utilized by the Parker Pen Company, c. 1946-1999

Source: Wisconsin Historic Museum Object #2001.51.1

Detail from the lathe

How did the lathe work? Step One: The operator placed a formerly formed metal cap or barrel blank in to the chuck, which held it in position by vacuum suction.Step Two: Operator pulled the left hands cutting tool, installed on a mix slide, towards herself to chop the job piece to length.Step Three: Operator moved a reaming bit, locked in the lathe’s turret, inward from the authority to complete the cut edge.

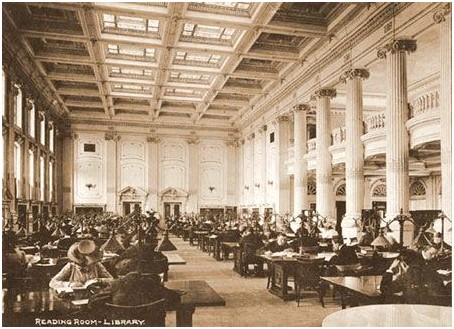

Parker Pen Company factory, c. 1925

Workers making pen components within the screw machine department, Parker Pen Co., Janesville, Wisconsin, c. 1925. The ladies in the left are operating lathes similar to the museum’s example, merely a generation earlier. In 1930, 500 or Parker’s 750 workers were women. See the original source document: WHI 39877

Parker pens, 1981

Silver, gold-plated, and stainless caps and barrels such as these were created about this machine. Source: Image in the Parker Pen Company 90-Second Annual Report, 1981

Trim lathe utilized by the Parker Pen Company of Janesville, Wisconsin to fabricate pen barrels and caps, c. 1946-1999.

(Museum Object #2001.51.1)

The Parker Pen Company purchased this trim lathe machine soon after The Second World War. Made by the Elgin Tool Works of Chicago, Illinois, it’s a bench-size, multi-purpose turret lathe setup for any specific, pen manufacturing task. Parker workers known as it a trim lathe since it was utilized to chop metal blanks for pen barrels or caps for their finished length.

To supplement his modest salary like a teacher in the Valentine School of Telegraphy in Janesville, Parker grew to become a salesperson for that John Holland Gold Pen Co. of Cincinnati. Alarmed through the unreliability from the pens he offered to his students, and feeling obliged to repair them, Parker learned fountain pen repair and grew to become convinced he could design a much better pen themself.

The primary challenges of fountain pen design would supply ink dependably where and when it had been wanted, and it from emerging at every other time or location. Parker started commissioning pens of their own design from another manufacturer in 1888, and received his first patent, to have an improved ink feed, on December 10, 1889. With capital provided with a new partner, insurance agent W.F. Palmer, the Parker Pen Co. was formally incorporated in 1892.

The Parker Pen Co. prospered on a mix of technical innovation and marketing skill. Within the next several decades, George Parker ongoing to patent enhancements to ink feeding and leak prevention systems. The “Lucky Curve” design – which avoided leaks while transporting the pen in a person’s pocket – grew to become the business’s first commercial breakthrough in 1894. The organization adopted this with new technical features including modified feeds, leak pads, slip-on caps and mechanical ink filling systems. The pens incorprating these enhancements featured mother-of-gem inlay, Aztec figures, gold-filled snakes and a lot of other decorative patterns. Finally — and possibly most crucially — from the earliest years, Parker always supported its products with national promotional initiatives.

Parker Pen soon grew to become a stalwart from the Janesville economy in 1918, the organization achieved its first $1,000,000 sales year, and the year after started construction of the new, five story factory. The organization arrived at another milestone in 1921, using the strongly styled, orange-bodied Duofold pen. Within 4 years of their introduction, company sales quadrupled. Costing $7.00 (two times around a typical pen), the Duofold established an advertising and marketing strategy that will serve the organization well for the following six decades. The organization described this tactic in the 1974 annual report:

Parker, actually, positioned each cool product as a present – esteemed not just for functional performance, but because a standing-billed, tricky to find personal accessory.

Exactly the same high-finish strategy was conspicuously repeated for that Parker “51” (1941) and “75” (1963) models.

Parker emerged from The Second World War with more than 1500 Wisconsin employees along with a home plant almost 3 decades old. The organization immediately started planning expansion. In 1953 it opened up “Arrow Park” in Janesville, a brand new 226,000 sq . ft . factory outfitted with condition from the art automated manufacturing machinery.

Parker’s sales ongoing to burgeon with the 1960s and 70s, topping $100 million in 1974. Like a lot of the Wisconsin economy, however, the organization faltered within the recession from the early 1980s. Among declining sales, Parker management committed to a change of Arrow Park, installing newer, more automated manufacturing equipment. This lathe is among the couple of machines of their vintage to outlive the mid-1980s upgrade, most likely since it was small, affordable, and reliable. Outfitted with new pneumatic lines along with a Leeson 1/3 HP motor unit, it ongoing for use between 1985 and 1995, probably for brief runs of custom-designed pens.

In 1986, several Parker’s British executives and investors acquired the Writing Instrument Division inside a leveraged buy-out, moving the organization headquarters to Newhaven, England and “

“

downsizing” the Janesville work pressure. Seven years later, in 1993, the proprietors offered Parker Pen Holdings, Limited. towards the Gillette Company. Gillette struggled integrating Parker into its Papermate and Waterman pen lines. Confronted with declining stationery sales along with a global manufacturing overcapacity, Gillette made the decision to shut the Arrow Park plant in 2000. It offered its writing instrument division to Newell Rubbermaid Corporation. a couple of several weeks later. Today, “Parker” is not a business, but a product put on pens made at factories all over the world.

[Sources: Parker Pen Company Annual Reports, 1939-1985 Bowen, Glen. “Collectible Fountain Pens: Parker, Sheaffer, Wahl-Eversharp, Waterman” (Glenview, IL: Glen Bowen Communications, 1982.) Fischler, George and Stuart Schneider, “Fountain Pens and Pencils: The Golden Chronilogical age of Pencils”, second rev. erectile dysfunction. (Atglen, PA: Schiffer Publishing, 1998).]

Source: www.wisconsinhistory.org