Navigation article:

A ballpoint pen is really a writing instrument featuring some advice that’s instantly refreshed with ink. It includes a precisely created metal ball sitting down inside a socket below a reservoir of ink. Because the pen is moved along a writing surface, ink is delivered. Despite the fact that ballpoint pens were first patented within the late nineteenth century, they merely began to achieve commercial significance in early 1950s. Now, ballpoint pens dominate the writing instrument market, selling more than one hundred million pens every year worldwide.

While the thought of a ballpoint pen have been around for several years, it required three different inventors and almost six decades to build up this contemporary writing instrument. The very first patent with this invention was issued on October 30, 1888, to some person called John J. Loud. His ballpoint pen contained a small rotating ball bearing which was constantly coated with ink with a reservoir above it. Although this invention labored, it wasn’t perfect for paper since it leaked and caused smearing. Two other inventors, Ladislas Biro and the brother Georg, improved on Loud’s invention and patented their very own version, which grew to become the very first commercially significant ballpoint pen. These pens still leaked, although not as badly. They grew to become popular worldwide, reaching the peak of sales in the mid 1940s. The following year another inventor, Baron Marcel Bich, finally solved the leakage problem and started manufacturing Bic pens in Paris. Through the years, many enhancements happen to be produced in we’ve got the technology and excellence of the different areas of the pen, like the ink, the ball, the reservoir, and the entire body.

Background

The ballpoint pen was created as a strategy to the issues associated with writing having a fountain pen. Fountain pens require user to constantly refresh the pen by dipping its tip in ink. This isn’t necessary having a ballpoint pen since it is made with its very own ink reservoir, which utilizes capillary action to help keep a lot of it from dripping out. In the tip from the pen is really a freely rotating ball sitting down inside a socket. Only thing about this ball is uncovered the remainder of it’s within the pen and it is constantly being bathed by ink in the reservoir. Pressing the end from the pen around the writing surface causes the ball to roll. This moving action then transfers ink from inside from the pen towards the writing surface.

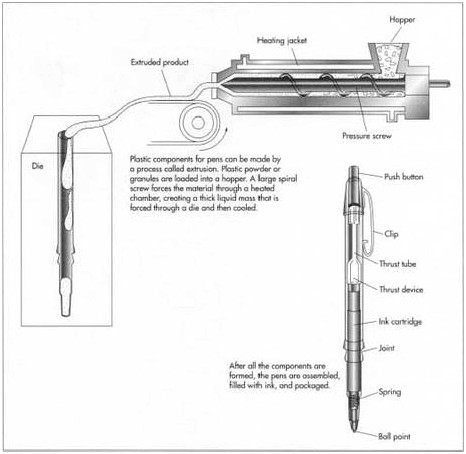

While different types of ballpoint pens can be found, most of the components are identical. Common components incorporate a ball, a place, ink, an ink reservoir or cartridge, as well as an outer housing. Some pens are capped having a cap to avoid it from dripping or getting its point broken. Other pens make use of a retracting point system for the similar reason. Here a little spring is connected to the outdoors from the ink reservoir, so when a control button is pressed, the thing is either uncovered or retracted. Still other types of ballpoint pens have multiple inkjet cartridges, to be able to write in various colors one pen. Other pens have refillable inkjet cartridges. One sort of pen includes a pressurized cartridge that allows the consumer to create underwater, over grease, as well as in space.

Recycleables

A number of recycleables can be used for making the constituents of the ballpoint pen, including metals, plastics, along with other chemicals. When ballpoint pens were first developed, a regular steel ball was utilized. That ball has since been substituted with a textured tungsten carbide ball. These components is superior since it is particularly resistant against deforming. The ball is made to be considered a perfect sphere that may literally grip nearly any writing surface. Its surface is really made up of 50 plus,000 polished surfaces and pits. The pits are connected by a number of channels which are continuous through the entire sphere. This design enables a lot of it to become present on the top and interior from the ball.

What exactly on most ballpoint pens are made from brass, that is an alloy of copper and zinc. These components can be used due to its strength, potential to deal with corrosion, appealing appearance, and skill to become easily created. Other areas, such as the ink cartridge, your body, or even the spring may also be created using brass. Aluminum can also be used in some instances to help make the pen body, and stainless may be used to make pen components. Gold and silver for example gold, silver, or platinum are plated onto more costly pens.

A lot of it could be specifically produced by the pen manufacturer. To become helpful inside a ballpoint pen, a lot of it should be slightly thick, slow drying within the reservoir, and free from particles. These traits be sure that the ink is constantly on the flow towards the paper without clogging the ball. Once the ink is around the paper, rapid drying occurs via transmission and a few evaporation. Within an ink formulation, various pigments and dyes are utilized to supply the color. Many other materials, for example lubricants, surfactants, thickeners, and preservatives, will also be incorporated. These components are usually spread in materials for example oleic acidity, using castor oil, or perhaps a sulfonamide plasticizer.

Before the creation of the pc, humans have scrambled to locate pencils to record story and song. The first scribbles were created having a burnt stick in sand. Through the 4th century B.C. , the Sumerians used wedge-formed reed pens to chop pictorial shapes into clay tablets. Eygptians colored hieroglyphics with brushes produced from marsh reeds and also the ancient Chinese authored with brushes of stiff hair. Ancient Romans and greeks sharpened stiff reeds to some extent, leading to chirography which was taut and precise.

The quill pen, produced from goose or swan down, was popular with authors for more than 1,000 years. The soft quill was honed to some extent, split in the tip allowing ink to circulate freely, and also resharpened. A monumental improvement within the quill pen was Frederick Gillott’s invention from the steel pen nib within the late nineteenth century, which needed no sharpening and is separated in the pen body and altered when needed. Still, the author constantly dipped pen into ink, wishing to prevent drips.

Fountain pens store ink in the reservoir inside the pen, the nib thus provided having a constant stream of ink. Alonzo Mix featured a “stylographic pen” by having an ink-depositing needle reason for the late 1860s, but blots and smears remained as common. However, the ballpoint pen virtually eradicated messes. Ballpoint pens manufactured at the start of a lifetime leaked, skipped, and dropped ink until 1950, whenever a new ink was created that made the ballpoint reliable.

Plastics have grown to be an essential raw material in ballpoint pen manufacture. They’ve the benefit of being easily created, lightweight, corrosion resistant, and affordable. They’re mainly accustomed to make up the body from the pen, but they are also used to help make the ink cartridge, the push button, the cap, and area of the tip. Different types of plastics are utilized, according to their physical characteristics. Thermosetting plastics, like phenolic resins, which remain permanently hard after being created and cooled, are usually utilized in constructing your body, cap, along with other pieces. Thermoplastic materials remain flexible. Included in this are materials like high-density polyethylene (HDPE) and

The Manufacturing

Process

Ballpoint pens are created to order in great quantities. While each manufacturer means they are slightly differently, the fundamental steps include ink compounding, metal component formation, plastic component molding, piece set up, packaging, labeling, and shipping. In advanced shops, pens will go from raw material to end product in under 5 minutes.

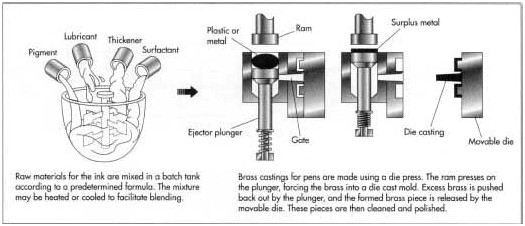

Making a lot of it

- 1 Large batches of ink come in a delegated part of the manufacturing facility. Here workers, referred to as compounders, follow formula instructions to create batches of ink. Recycleables are put in to the batch tank and completely mixed. With respect to the formula, these batches could be heated and cooled as essential to assist the recycleables combine more rapidly. A few of the bigger quantity recycleables are pumped and metered into the batch tank. This stuff are added by simply pressing a control button on computerized controls. These controls also regulate the blending speeds and also the cooling and heating rates. Qc checks are created during different points of ink batching.

Rubber stamping and developing

- 2 As the ink has been made, the metal aspects of the pen are now being built. The tungsten carbide balls are usually provided by outdoors vendors. Other areas from the pen, like the point and the entire body, are created using various molds. First, bands of brass are instantly placed into rubber stamping machines, which eliminate a large number of small dvds. The brass dvds are next softened and put right into a compression chamber, featuring its a steel ram along with a spring-backed ejector plunger. The steel ram presses around the metal, resulting in the plunger to retract and forcing the metal right into a die cast mold. This compresses the metal and forms the different pen pieces. Once the ram and plunger go back to their original positions, the surplus metal will be crawled off and recycled. The die will be opened up, and also the pen piece is ejected.

- 3 The created pieces will be cleaned and cut. They’re immersed inside a bath to get rid of oils utilized in the molding process. Once they leave the tub, the various components will be cut to the length of the particular pen. The pen pieces are next polished by rotating brushes and cleaned again to get rid of any residual oils. The ball may then be placed in to the point cavity.

Molding the housing

- 4 The plastic aspects of the pen are built concurrently using the

Ink filling and set up

- 6 Following the components are created, set up can occur. Typically, the ballpoint is first connected to the ink reservoir. These pieces will be conveyored to injectors, which fill the reservoir using the appropriately colored ink. If your spring will probably be present, this will make it put on the barrel from the reservoir.

Final set up, packaging, and shipping

- 7 The purpose and reservoir will be placed within the primary body from the pen. At this time, other components like the cap and ends are incorporated. Other finishing steps, for example adding coatings or adornments or conducting a final cleaning, will also be done. The finished pens will be packaged based on how they’ll be offered. Single pens may be put into blister packages with card board backings. Categories of pens are packed into bags or boxes. These sales units will be put in boxes, stacked on pallets, and shipped to distributors.

Qc

The caliber of pen components is checked during all manufacturing stages. Since a large number of parts are created every day, inspecting each is impossible. Consequently, line inspectors take random examples of pen pieces at certain time times and appearance to make sure that they meet set specifications for size, shape, and consistency. The main testing technique is visual inspection, although more rigorous measurements will also be made. Various calculating equipment can be found. Length measurements are created having a vernier caliper, a micrometer, or perhaps a microscope. All these differ in precision and application. To check the health of surface coatings, an optical flat or surface gauge can be utilized.

Such as the solid bits of the pens, quality exams are also performed around the liquid batches of ink. In the end the components are put into the batch, an example is come to the standard Control (QC) laboratory for testing. Physical characteristics are checked to make certain the batch adheres towards the specifications outlined within the formula instructions. The QC group runs tests for example pH determination, viscosity checks, and search evaluations. When the batch is discovered to be “from spec,” adjustments can be created. For example, colors could be adjusted with the addition of more dye.

Additionally to those specific tests, line inspectors will also be published each and every phase of manufacture. They visually inspect the constituents because they are made and appearance for items like inadequately filled ink reservoirs, deformed pens, and incorrectly put together parts. Random examples of the ultimate product will also be tested to make sure a load of pens writes properly.

The Long Run

Ballpoint pen technologies have improved greatly because the duration of Loud’s first patented invention. Future research will concentrate on developing new inks and designed pens which are much more comfortable and more durable. Furthermore, manufacturers will make an effort to produce greater quality products in the cheapest possible cost. One trend which will continue would be the growth and development of materials and procedures designed to use metals and plastics which have gone through no less than processing using their normal condition. This will minimize waste, increase production speed, and lower the total price of the pens.

Where to find out more

Carraher, Charles, and Raymond Seymour. Polymer Chemistry. Marcel Dekker, 1992.

Periodicals

Peeler, Tom. “The Ball-Point’s Bad Beginnings.” Invention & Technology, Winter 1996, p. 64.

Trebilcock, Bob. “The Leaky Legacy of John J. Loud.” Yankee, March 1989, p. 141.

Source: www.madehow.com